Services

Our Innovation and development service in industrial filtration processes has been developed in our company through the synergy between advanced technologies to perform simulations of filtering processes in fluids, our years of experience in the industrial sector and the high skills of our staff .

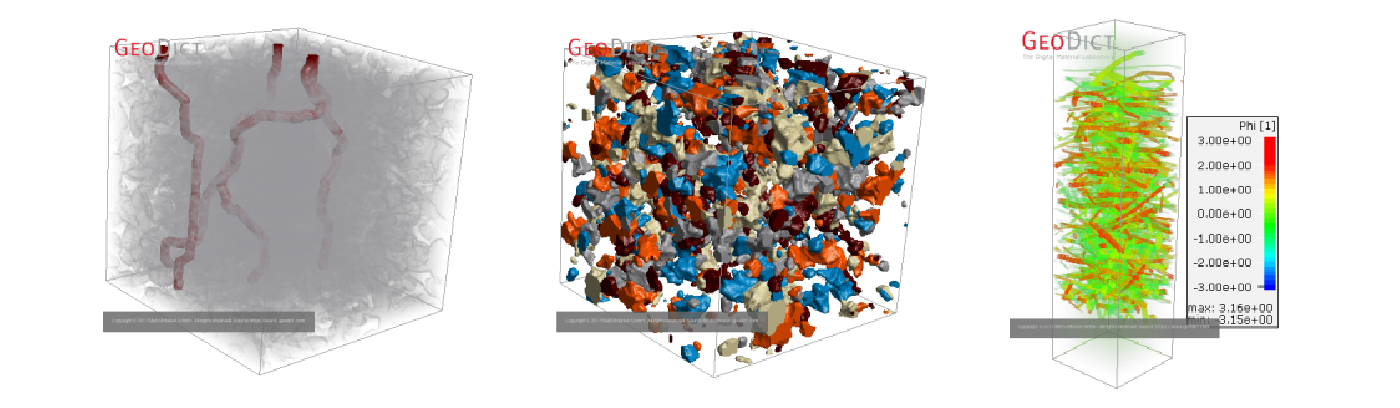

Our services include interface tools to import and segment filter material and tissue image data using microCT and FIB / SEM images and material modeling functions to design 3D models from user-defined specifications, along with predictors of material properties to analyze them.

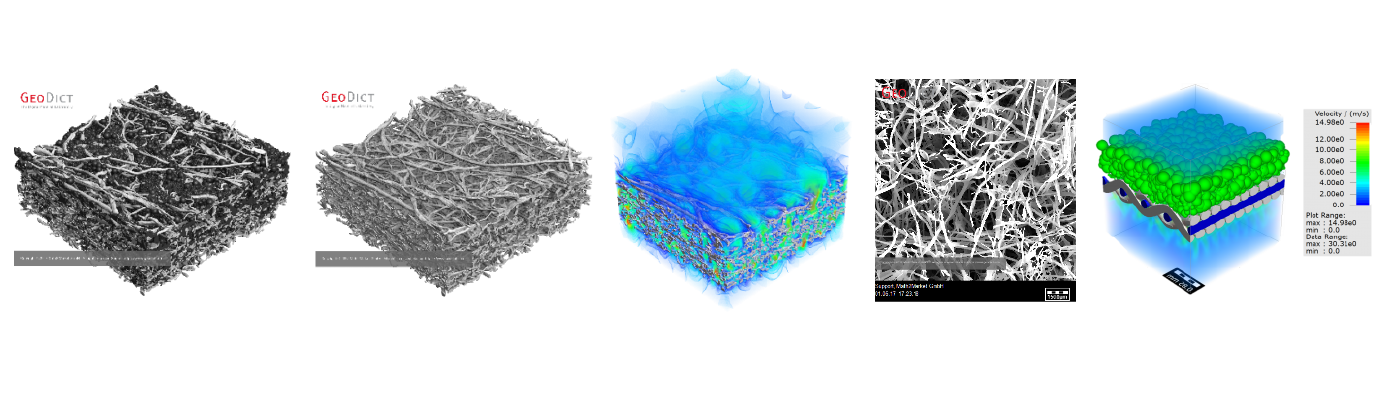

Our filter material microstructure analysis service is the most complete solution for the processing of imported 3D images from microCt and multi-scale FIB / SEM, the modeling of the materials, the visualization, the characterization of the material goods, the development material based on simulation and process optimization. Our analysis process begins with the importation of materials in from computerized tomography or from formats already established in our system. Our systems can model materials from scratch, according to the parameters given in the data sheets or following original and unique designs.

With the definition of the materials in our system, new knowledge can be obtained quickly and easily, and as a first step towards improvement. Through simulations, we are able to predict the behavior of materials to drastically reduce costly and time-consuming prototyping in analysis and development. Among the Benefits in the use of our service we can highlight: Repeated and non-destructive prediction of the properties of the materials. Reduction, or even elimination, of the need for costly and time-consuming laboratory tests. Simulation-based design of innovative materials to suit the requirements of many industrial sector.

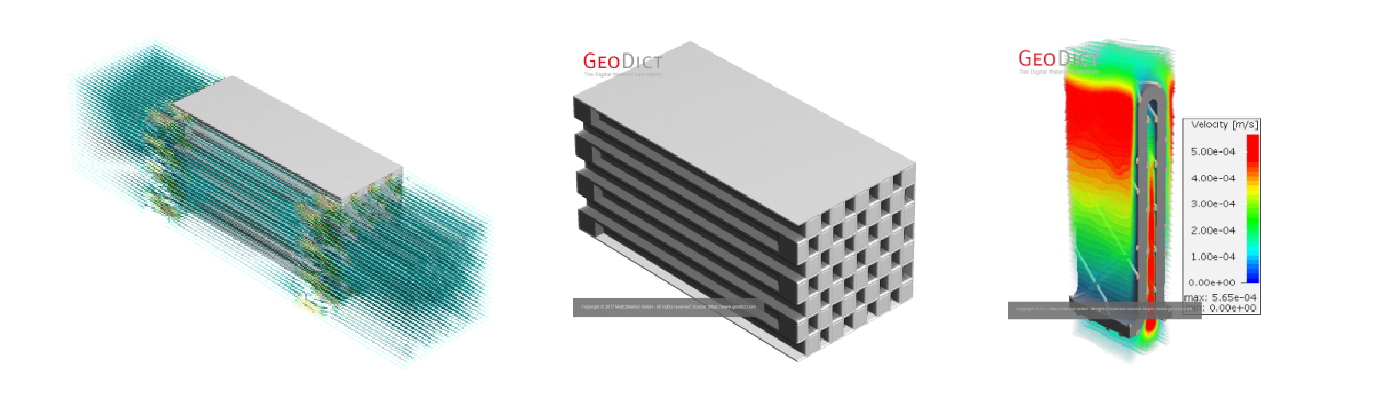

Our simulation service for filter media analysis aims to determine the useful life and dust retention capacity of a filter element, with a smooth or pleated structure. Our service is fully capable of simulating the clogging of a filter in a single pass experiment in an unresolved medium, such as single or multiple pleat elements, structures of diesel particulate filters, etc. The pass-through model is implemented, which considers the possibility of filtration of each type of particle in different types of unresolved porous media. The evolution of the pressure drop and the fractional efficiencies are determined over time and the DHC.

The simulation covers the entire filtration regime, from depth filtration to cake filtration. Pleated filters can be optimized and / or redesigned by choosing flat sheet filter media and specifying the geometry and number of pleats. The simulation we carry out is validated by comparing the results with experiments and adjusting the numerical parameters. Our advanced service in Filter Analysis includes: Tracking particles through a crease element. Soot filtration simulation through a honeycomb structure of a diesel / gasoline particulate filter. Clogging simulation of a high efficiency particulate air (HEPA) filter pleat.

Our filter media analysis service is able to determine: Initial filter efficiency: Determines the filter efficiency and the most penetrating particle size of a filter media by tracking particles through a 3D filter structure. The simulation of particle motion can include interception, inertial impact, Brownian motion, and electrostatic attraction. Various physical models are available to model the contact of a particle with the filter media (captured at first touch, Van der Waals forces / Hamaker’s constant, sieved) and allow modeling of different filtration regimes.

User-defined functions allow full control of these model parameters. Initial Pressure Drop – Determines the initial pressure drop over the filter media. Fast flows are modeled with Navier-Stokes, slow flows with the Stokes equation. Filter duration and capacity: Our service is in the ability to simulate the clogging of a filter in a single-step or multi-step experiment. The evolution of the pressure drop over time and the dust holding capacity are determined. The simulation covers the full range from depth to cake filtration

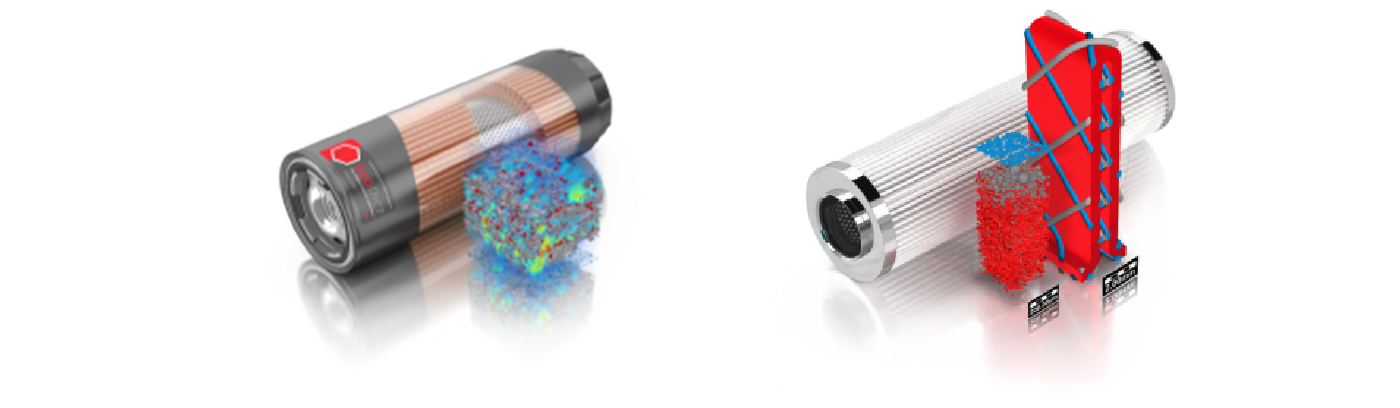

Within our robust comprehensive filtration systems analysis service, we managed to include filter housings in their interaction with filters, filter media and flow simulations. Filtration systems are critical factors in industry and in everyday life, to preserve the functionality of the machine and to protect against toxic and allergenic substances. The demands on filter efficiency, selectivity, capacity and service life are constantly increasing and highly specialized solutions are needed for every filtration application. This is due to: The complex interaction of the material properties of the filter media. The arrangement and shape of the fibers in the middle. The physical and chemical properties of the fluid being filtered. The characteristics of the particles in the fluid. The traditional way of designing, building,

And testing filter prototypes is costly in time and resources. Simulated and calculated parameters for the improvement and design of filters in air, gas and liquid filtration: Nonwovens, fabrics, foams, sintered ceramics, membranes, pleats and support meshes, wire and plastic meshes. Medium thickness, fiber diameters, fiber orientation, grammage, pore size distribution, bubble point, percolation path. Single and multi-pass tests, diesel soot test dust, standard aerosol test powders, standard test powders. Filtration of soot in a diesel particulate filter (DPF) or a gasoline particulate filter (GPF). Initial pressure drop, pressure drop evolution, initial filter efficiency, fractional efficiencies, filter capacity, filter class and MPPS. Movement of particles and deposition of particles in the filter medium, clogging behavior of the filter and filtration of the cake.

The specific properties of a wire cloth can be precisely described and defined geometrically by the type of weave, wire diameter and mesh counts. Profiltech uses the GeoDict software to determine in advance the best suited cloth configuration for the particular area of application. By simulating different situations, it is possible to optimize existing wire cloth specifications and develop new ones. Simulation | 3D Cloth Model Using specific cloth parameters resulting from the type of weave, aperture size, pitch and wire diameter, Profiltech can depict the structure of single layer cloths and multiple layer cloths as a real 3D cloth model.

Simulation | Flow Behaviour Behaviour of the respective cloth or cloth laminate in various fluids such as air, water and fuel as a function of flow velocity or differential pressure.

Simulation | Geometric Pore Size For the geometric pore size, a characteristic value is determined that describes the diameter of a round sphere that is just able to pass through the wire mesh. For the pore size (PG), Profiltech states the value Xmax (= maximum pore size) as reference.

Simulation | Calendering Calendering reduces the cloth to a predetermined thickness between two steel rollers. The cloth becomes more non-displaceable, the wire crests are flattened, the smoothed surface is adapted to following production and application purposes.

If you have any suggestions or concerns, we are available to address them. Let us know how we can help you.